Hi

@hightechnature , I'll try and detail the epoxy fill/self tapping screw method a bit better here.

First you have to remove the rear fender, and position it bottom side up. Next clean up the holes in the plastic where the inserts were, removing any loose debris. I drilled a few small .05 holes in the sides of the insert bosses to allow some epoxy to ooze out for extra bite, this step may not be necessary.

Next I fill the hole to the top with a 2 part epoxy, I’ve tried several flavors but had the best luck with JB Weld 50132 “PlasticWeld”. Regular JB weld gets too hard and will tend to crack when driving in the self tapping screws. When filling the holes, try and force as many air bubbles out as possible, a toothpick helps. Once the epoxy is properly cured drill the specified size hole for the size fastener you will be using.

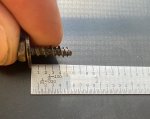

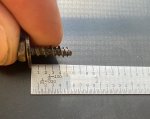

This is what I had laying around that I used;

The following part isn’t the exact screw I used but is the same size and type (but with a Phillips head).

McMaster-Carr

You can find different head styles and materials through McMaster Carr. Reinstall fender, if using the screw size I listed you can also use the tiny compression limiters if you still have them.

This repair lasted me almost 1k miles on my bike and was only done in by a particularly rough track day. I’m fairly confident it will hold up well for most applications.

Sorry, I didn’t take any additional pictures in process unfortunately. I’ll try and address any other questions should they come up.